- Call us

- +49 2561 / 9384-0

- Mail us

- info@ab-maschinen.de

- Opening hours

- Show opening hours ›

- Contact

- Information ›

DURMA | HAP 30.120

- Metal Processing

- Sheet metal working / shaeres / bending

- Hydr. pressbrake

Details

- Control type

- NC

- Year of manufacture

- 2006

- Stock number

- 1008-9308467

- Manufacturer

- DURMA

- Storage location

- Ahaus

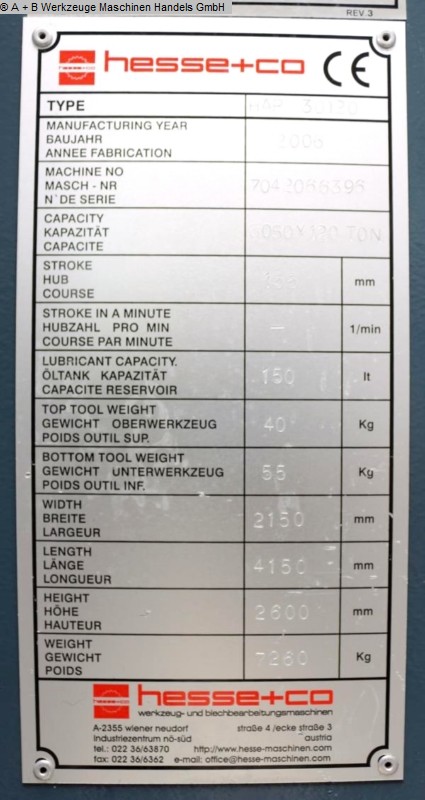

Technical specifications

- pressure:

- 120 t

- chamfer lenght:

- 3050 mm

- distance between columns:

- 2550 mm

- stroke of upper beam:

- 155 mm

- throat:

- 350 mm

- ajustment speed:

- 100 mm/sec

- working feed:

- 9.0 mm/sec

- return speed:

- 77.0 mm/sec

- Control:

- ENC 310

- work height max.:

- 878 mm

- table width:

- 104 mm

- oil volume:

- 150 l

- total power requirement:

- 11.0 kW

- weight:

- 7260 kg

- range L-W-H:

- 4150 x 2150 x 2600 mm

Description

** New price ~ 50,000

** From a maintenance workshop - good condition (!!)

Equipment:

- NC electro-hydraulic press brakes

- With DURMA NC control "ENC 310"

* 128x64 pixel LCD display, illuminated

* 30 programs with 20 steps each

* Manual/semi-automatic/automatic operating mode selectable

- Pivoting control panel, front left

- NC-controlled axes: Y1 + Y2 + X

- NC electro-motorized backgauge (X axis)

* With 2x manually adjustable stop fingers

* Including lateral and height adjustment (Z + R axes)

- FIESSLER laser safety device at the front

- Manual bending table crowning

* Adjustment via hand crank

* With analog value display

- AMADA/PROMECAM upper tool holder

* With upper wedge crowning & quick-change adapter

* Split Deer-foot upper tool (AMADA)

- AMADA/PROMECAM lower tool holder

* Split 4V universal die, in the die shoe

- 2x front support arms

- Side guard (hinged doors)

- Rear guard (hinged door)

- 1x freely movable foot switch

- Operating instructions (PDF)

Enquiry

Technical specifications

- pressure:

- 120 t

- chamfer lenght:

- 3050 mm

- distance between columns:

- 2550 mm

- stroke of upper beam:

- 155 mm

- throat:

- 350 mm

- ajustment speed:

- 100 mm/sec

- working feed:

- 9.0 mm/sec

- return speed:

- 77.0 mm/sec

- Control:

- ENC 310

- work height max.:

- 878 mm

- table width:

- 104 mm

- oil volume:

- 150 l

- total power requirement:

- 11.0 kW

- weight:

- 7260 kg

- range L-W-H:

- 4150 x 2150 x 2600 mm